Discussion Paper – Recycled Mulch

Addressing Challenges and Promoting Sustainability in the Recycled Mulch and Timber Recycling Industry

The recent string of incidents, including asbestos contamination and fires in timber recycling facilities across multiple states, has raised significant concerns within the industry. These occurrences underscore the importance of ensuring the quality of products and the long-term viability of the recycled mulch and timber recycling sector.

As regulators and specifiers increasingly intervene to manage risks to the environment, the community, and project integrity, it is evident that now is a pivotal moment for collective action.

For over four decades, the recycled mulch and timber recycling industry has been crucial in diverting materials from landfills and processing timber waste into garden mulch and compost products.

However, shifts in the waste stream, characterised by decreased hardwoods and increased processed and treated timbers, pose new challenges. The rise in treated timber, driven by the substitution of softwood for hardwood and chemical treatments to enhance durability, necessitates stringent quality control measures.

Recycled Mulch and Timber Recycling in Victoria

In Victoria, landscape mulches are sourced from various materials, each with its own set of strengths and weaknesses. While forestry residues offer cleanliness, their limited availability and high transportation costs present logistical challenges.

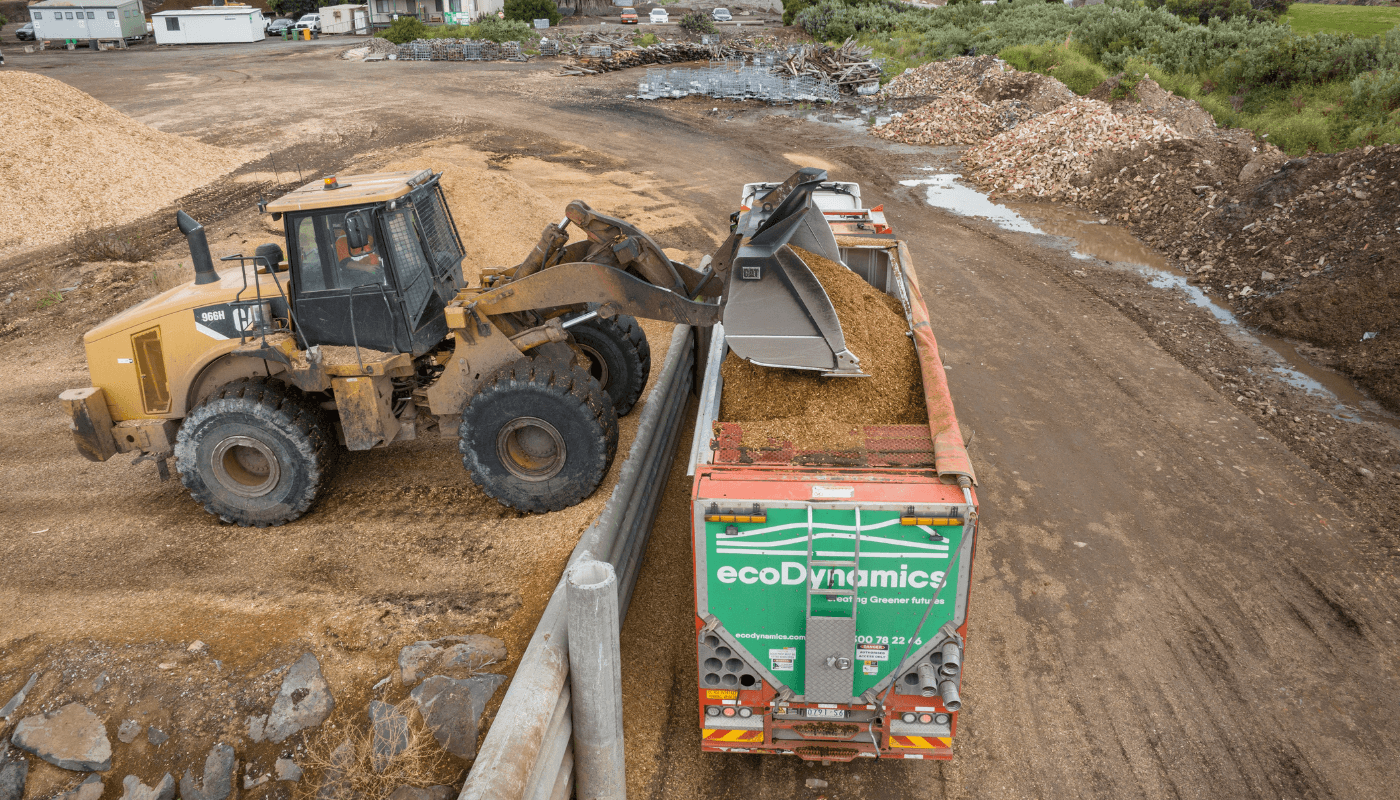

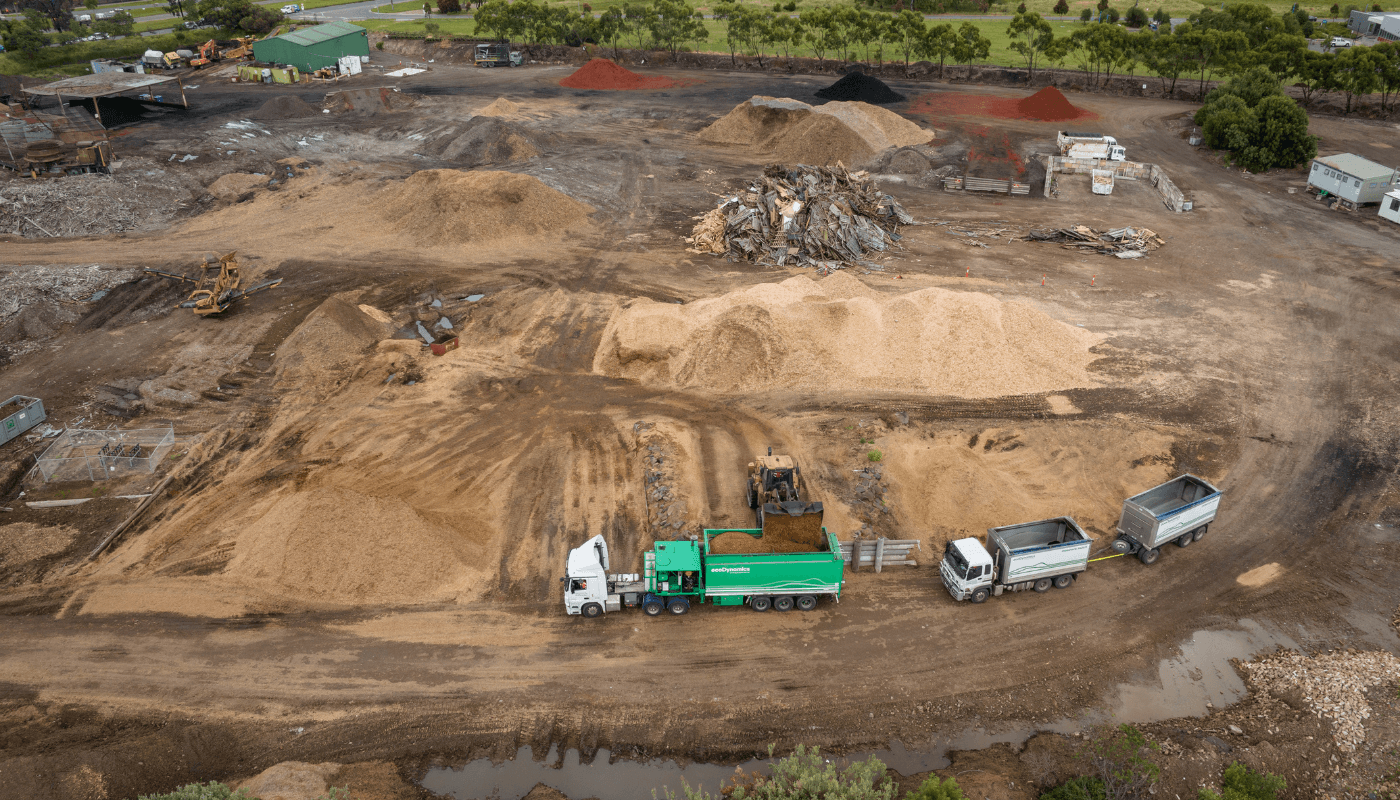

As our primary resources, we specialise in utilising forestry residues, such as pine bark and pine chips, alongside recycled timber. These forestry residues are sourced from managed plantations, ensuring their cleanliness and sustainability.

However, their availability is constrained, and their transportation over significant distances adds to their cost and carbon footprint.

Recycled timber, sourced from various sources such as fencing, packaging and pallets, industrial waste (timber offcuts from framers) and demolition waste, poses contamination risks that must be effectively managed.

Preventing contaminants from entering recycling facilities is crucial, as once they enter the processing stream, managing or removing them becomes difficult.

Recycled Mulch and Timber Recycling Regulations in Victoria

The regulatory environment in Victoria has undergone recent changes, with the EPA taking a more proactive role in monitoring timber recycling operations. While these efforts aim to enhance environmental protection, concerns have been raised about their impact on the industry’s ability to deliver sustainable solutions.

Some operators have expressed reluctance to engage in recycling activities due to perceived regulatory burdens and risk, leading to increased timber disposal to landfills.

Mulch quality is regulated by AS4454 Composts, Soil Conditioners, and Mulches and project-specific specifications. While these standards ensure product safety, there is growing recognition of the need to review them to allow for greater flexibility in selecting mulches based on specific contexts and risk considerations.

For instance, playground mulches necessitate distinct functional and safety criteria compared to those employed in freeway reserves. Customising mulch selection in this manner ensures optimal suitability and mitigates potential hazards in diverse settings.

This approach will enable stakeholders to balance safety and sustainability outcomes, ensuring that recycled timbers are utilised effectively without compromising environmental integrity.

To maintain the integrity of our site and prevent contamination, we implement a rigorous screening process for all incoming loads. This involves thoroughly assessing the source of materials and promptly rejecting any loads containing demolition or fencing timber, which are potential sources of contaminants.

Additionally, we conduct two thorough inspections of each load: one before unloading and another during the unloading process itself. Any identified contaminants are promptly removed upon unloading, and in cases where contamination is deemed significant, entire loads are rejected outright.

This meticulous approach ensures that only clean and reliable materials are utilised in our operations, upholding our commitment to quality and environmental stewardship.

Efforts to address the changing nature of the waste stream, particularly the increase in engineered and treated timber, are ongoing.

By matching mulch standards to proposed end-use and adopting a realistic approach to risk management, stakeholders can ensure that clean recycled timbers are used in suitable ways and not consigned to landfills unnecessarily.

This approach will promote sustainability and support the long-term viability of the timber recycling industry.

Want more information?

Please contact ecoDynamics Group CEO Nick Somes.

m: 0407 871 046